Much ado about plastic

It keeps things fresher for longer, it’s tough, durable and adaptable. It fills up waste sites and oceans at an eye-watering rate. Plastic is a problem we can’t ignore. We’ve written this report in response to the packaging crisis.

It keeps things fresher for longer, it’s tough, durable and adaptable. It fills up waste sites and oceans at an eye-watering rate. Plastic is a problem we can’t ignore. We’ve written this report in response to the packaging crisis.

Contents

1) What is plastic and why is it a problem?

2) A short list of shocking plastic facts

3) Better Food’s Journey – reducing, reusing and recycling

4) The impact of so far of the changes we’ve made

5) In our cafes

6) Less crackable nuts and other harsh truths

9) Useful links and index of sources

1) What is plastic?

Plastic has been the material of choice for countless products for over 100 years. But what is it?

Propylene – a simple chemical component of petroleum – is heated to form chemical polymers, which fuse together with others in very strong carbon-carbon bonds. You can think of this like making a cake: once the ingredients have been baked there is no going back (1, see index) to the raw materials. However, unlike a cake, plastic doesn’t break down. This is because it takes billions of years for organisms to evolve to attack certain types of bonds, and carbon-carbon bonds are not found in nature.

However, it’s versatile – strong, lightweight, flexible and heat resistant – and handy in innumerable ways. It also plays an important role in, among many other things, tackling food waste.

Why has it become a problem?

Plastic was developed in the early 20th century, but only really took off in the 1960s when it fast became the symbol of 20th century living, making life simpler, cheaper, more hygienic and convenient. By the 1990s, unwrapped produce, glass and metal bottles, tin lunch boxes and cloth wrap were largely a thing of the past.

Today, plastic is a multibillion-dollar industry. The UK alone generates £23.5 billion in annual sales.

So maybe the issue isn’t plastic, the issue is our reliance on it as a packaging solution, and more crucially, our reliance on single use plastics.

2) A short list of shocking plastic facts

We never actually throw anything ‘away’ – we just put it somewhere else. Virtually every piece of plastic that was ever made still exists in some shape or form.

(https://advances.sciencemag.org/content/3/7/e1700782.full)

An estimated 8.3 billion tonnes of it have been produced in just 60 years.

(https://news.nationalgeographic.com/2017/07/plastic-produced-recycling-waste-ocean-trash-debris-environment/)

About half of all the plastic that’s ever been produced has been made in the past 15 years.

(https://advances.sciencemag.org/content/3/7/e1700782.full)

A million plastic bottles are sold around the world every minute.

(https://www.theguardian.com/environment/2017/jul/19/plastic-pollution-risks-near-permanent-contamination-of-natural-environment)

Plastic has been found in 59% of sea birds.

(https://oceanconservancy.org/trash-free-seas/)

91% of plastic isn’t recycled.

https://ourworldindata.org/faq-on-plastics#how-much-of-global-plastic-is-recycled

3) Better Food’s Journey – reducing, reusing and recycling

3) Better Food’s Journey – reducing, reusing and recycling

This picture is of our founder Phil Haughton in his first organic store, Real Food Supplies on Gloucester Road in Bristol in 1985. If you look closely, you’ll notice something – there is no plastic.

In those days, indeed until the early noughties, the organic market was niche. Organic goods were for the most part produced on a small scale, away from large manufacturing processes and complex packaging solutions. (In 1999, sales of organic in the UK totalled £384m – barely even registering on the index of food sales, compared with today, worth £2.4b – still only 1.5% of all food and drink sold in the UK.)

Move forward to 2019, and in many ways our grocery shelves have come to look more like those of conventional supermarkets. Our mission now is to rewind as much of this as we can.

We’ve already had some great successes in tackling the packaging problem. There are many potential solutions to each packaging conundrum we face, and received wisdom is evolving all the time. We’re chipping through the issues section by section, keeping a close eye on the latest advice and developing technologies. Take a look at our Low and no plastic and packaging shopping guide for an up to date look at what we’ve already implemented in our stores and cafés.

4) The impact of so far of the changes we’ve made

Focussing on our St Werburghs store, 1st September 2018 to 31st March 2019

Focussing on our St Werburghs store, 1st September 2018 to 31st March 2019

Prepacks replaced by Refill wall – 22,185 prepack bags across 44 lines

Based on pack sizes of equivalent products (500g, 250g, 150g or 125g, depending on product)

Liquid refills – household – 5,836 containers

Based on most common container size of equivalent products (1l, 75ml or 50ml, depending on product)

Liquid refills – Health and Bodycare – 1,648 containers

Based on most common container size of equivalent products (472ml, 400ml or 250ml, depending on product)

Loose leaf tea – 2,403 tea bag boxes and wraps – 42,000 teabags

Based on average weight of a teabag (2g), and average box size (for herbal teas – 20/box at between 20 and 40g/box)

Bread (excl Sundays) – 34,102 plastic bags

Based on unpackaged bread (loaves only) – Hobbs House and Bristol Loaf (excl Hobbs House bread on a Sunday)

Loose eggs – 2,092

Based on sales of 6 eggs, placed in reused egg boxes from customers and our suppliers

Unpackaged soap – 3,652 boxes/wraps

Based on sales of Faith in Nature unwrapped soap

Wine – 244 bottles

Based on sales of More Wine in 750ml reusable bottles

Fresh produce, by quantity sold unpackaged:

Carrots – 3,376 kg

Apples – 39,342 loose apples

Salad leaves – 220 x 100g

We sell many lines of fresh produce loose or in cardboard punnets (which we ask customers if they want to leave behind). The figures above are just a few examples of the full range we sell.

5) In our cafés

The section below (Bioplastic vs. RPET) takes a look at what we’re doing about deli packaging.

See Waste management (also below) about how our cafés help our whole business manage waste.

Our Refill water stations are open to everyone, customers or not. It gets used by passers by many times each day.

In addition, we encourage you to come armed with your own tubs and lunchboxes for takeaways, and to bring your own cups for takeaway drinks.

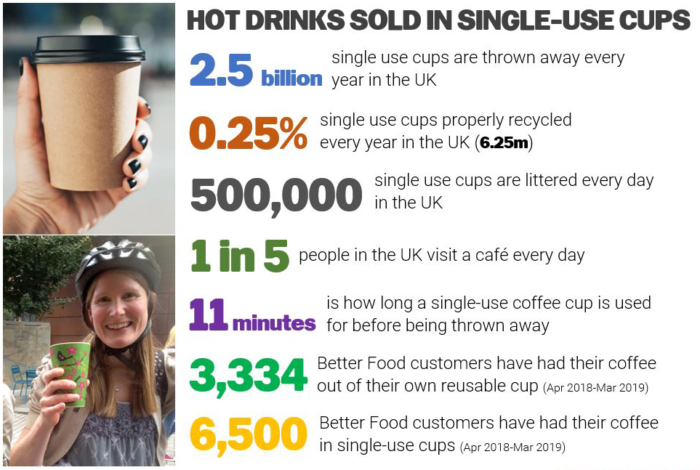

We charge a 10p levy if you use one of our takeaway cups (currently from Vegware), which we donate to the Soil Association. We raised £646.10 between 1 April 2018 and 31 March 2019 this way – that’s a whopping 6,461 cups used for an average of 11 minutes each before being thrown in the bin …

This infographic looks at the problem of coffee cup waste.

6) Less crackable nuts and other harsh truths

It’s fair to say that some of the packaging conundrums we’re facing are easier to grapple with than others. Many of our suppliers run small-scale businesses that are a labour of love rather than huge money-making enterprises. In some cases, and not through a lack of intent, they are slower to respond than others due to costs and many other barriers to reducing plastic in their supply chains. We want to provide a balance between keeping a certain amount of pressure on them, whilst not bullying them into change before they’re able to embrace it.

The idea of goods being ‘packaging-free’ is also a bit of a misnomer, because much of the range does actually arrive to us in large plastic bags. Whilst most of the grain, pulses and flour comes in paper or hessian sacks, dried fruit, nuts, loose leaf tea and frozen fruit and veg all come to us in plastic bags or containers. However, buying in this way still significantly reduces the overall amount of plastic packaging generated through the sale of these lines and we do recycle soft plastic, which is a service not currently provided at a municipal level.

Our household and bodycare refills also come in large containers. Currently these are also recycled. We are changing to a new system of refillable kegs over the summer (of 2019)

7) Waste management

Part of our business model is that our central kitchen and cafés are able take on food that’s coming to the end of its shelf life in our stores. If we have a glut of something, it will appear on the café menus soon after.

When we do have leftover stock that isn’t good enough to sell but is still perfectly edible, it’s offered to staff.

Staff are offered vegetable soup and yesterday’s bread for lunch every day, as a way of managing veg and bread waste – about 60% of us eat it and it’s delicious.

For our St Werburghs and Whiteladies Road stores, our waste is managed by Hills Waste Management. Food waste goes to Geneco’s anaerobic digestor (AD) in Avonmouth (this blog from Opus Energy illustrates the AD process clearly). Glass, cardboard and plastic waste end up in the appropriate recycling plants. Anything that can’t be treated in the above ways is incinerated to become Energy from Waste (also known as Waste to Energy).

Due to bin storage space (or lack of), our Wapping Wharf store use onsite recycling and waste to energy facilities provided by our landlord, Umberslade.

If you have any ideas or suggestions of plastic or packaging free things you’d like to see in ours stores, please do get in touch.

Better Food’s evolving plastic and packaging strategy: learn, test, adapt, reflect.

8) Bioplastic vs. RPET

What is bioplastic?

Bioplastic is a material made from plants instead of petroleum. Bioplastic food packaging is usually made by extracting sugar from corn and sugarcane and converting into polylactic acids (PLAs). While it sounds great, it’s currently not so straight forward, for several reasons.

Why is it a problem?

Firstly, as an organic retailer, bioplastic made from corn starch is especially problematic as the corn used comes from monocrops imported from US that use GM and non-organic compliant herbicides.

Secondly, though technically compostable, in reality there are very few industrial composting facilities nearby that are able to deal with bioplastic. Bristol Waste and the surrounding councils use recycling facilities to deal with plastic waste, and anaerobic digestors to deal with food waste. Bioplastic is a problem because it doesn’t fall into either of these waste streams. It’s not plastic and therefore not recyclable, and it won’t break down in an anaerobic digestor because is requires an aerobic process. The two systems – composting and anaerobic digesting – are opposites, one relying on the presence of oxygen, and the other requiring the absence of oxygen. A good explanation of the two sciences can be found here on the Recycling and Waste World’s website.

Thirdly, turning plants into plastic (to make bioplastic) is currently more energy intensive than recycling used plastic.

The word ‘compostable’ might lead you to think you can put bioplastic into your home compost bin, and with some of the cardboard-like items (like sandwich boxes) you can (though only 3% of the population compost). However, this isn’t the case for the rigid items such as the hard, clear pots used in our delis, because domestic composting doesn’t reach the temperatures needed. So the best way to dispose of bioplastic packaging at home is to put it in your black wheelie bin where it will go into general waste and be incinerated (and used as Waste for Energy) or go to landfill.

What’s the solution?

There are circumstances where using bioplastic as take away packaging works really well, such as in ‘closed loop’ scenarios like university campuses, in schools and to some degree at festivals (though experiments have only had modest success, and ‘contamination’ of bioplastic bins is high).

Bioplastic may well yet have its day, but for now, we’re changing our deli pots (used for our deli hummus etc) to those made from RPET (Recycled polyethylene terephthalate – the most commonly used hard clear plastic). It’s recycled and recyclable, so while it’s certainly not perfect (no single use plastic is perfect), it is at least being reused and is reusable (in its recyclability).

Have a look at this short film made by City to Sea.

9) Useful links and index of sources

9) Useful links and index of sources

Spear-headed by local eco-warrior Natalie Fee, City to Sea and Refill are Bristol-based campaign groups whose ideas and impact are now reaching well into Europe and beyond. Have a look at Things You Can Do.

City to Sea are our partners and guide on all things reuse, refill and recycle (thanks also to Sustainability and Behaviour Change Consultant Livvy Drake)

Bristol Waste Company are our local council-owned custodian of rubbish. Bristol Recycling in Pictures is particularly informative.

Bristol Waste Company are our local council-owned custodian of rubbish. Bristol Recycling in Pictures is particularly informative.

WRAP (Waste Reduction Action Programme) is a registered charity set up by the government, working to transition businesses and organisations towards a circular economy. They have lots of interesting, fact-filled reports on their website.

Ellen MacArthur Foundation is working to accelerate the transition to a circular economy across five areas to bring positive economic change on a global level. An inspiring and fascinating alternative solution to a failing linear economic model.

Geneco collect Bristol’s curb side food waste and take it to their anaerobic digestion plant in Avonmouth. They turn it into renewable energy, some of which is fed back into the national grid, and some of which is turned into biomethane, used to power the lorries that collect the waste and as an agricultural biofertilizer … who said waste management was boring!

Also thanks to Sophie Laggan for her initial research.

Plastic facts

- (1) Interestingly, there is a process to turn plastic back into oil, but with the discovery of new sources of oil there was no economic benefit to be had from the technology to it just sort of slipped into the shadows. See https://www.bbc.co.uk/programmes/m0005mpm

- http://www.bpf.co.uk/Industry/Default.aspx

- https://www.earthday.org/2018/03/07/fact-sheet-end-plastic-pollution/#_ftn3

- https://advances.sciencemag.org/content/3/7/e1700782.full

- https://news.nationalgeographic.com/2017/07/plastic-produced-recycling-waste-ocean-trash-debris-environment

- https://www.theguardian.com/environment/2017/jul/19/plastic-pollution-risks-near-permanent-contamination-of-natural-environment

- https://oceanconservancy.org/trash-free-seas

- https://ourworldindata.org/faq-on-plastics#how-much-of-global-plastic-is-recycled

Organic spend

- https://www.telegraph.co.uk/news/science/science-news/3321948/Spending-on-organic-food-trebles-since-1990s.html

- https://www.soilassociation.org/media/18224/omr-report-2019-interactive.pdf

Waste management

- https://www.bristolwastecompany.co.uk

- https://www.ellenmacarthurfoundation.org

- http://www.wrap.org.uk

- https://www.geneco.uk.com

- https://www.hills-waste.co.uk

- http://www.opusenergyblog.com/illustrated-step-step-guide-anaerobic-digestion

Composting vs. recycling

- http://www.recyclingwasteworld.co.uk/in-depth-article/whats-the-problem-with-plant-based-packaging/178541/

- https://www.businesswaste.co.uk/97-of-uk-households-dont-compost-britain-forgets-the-art-of-composting/#.XO0wYqBKiUk

- https://www.drbronner.co.uk/about/packaging-innovations

- https://www.citytosea.org.uk/